My service progress:

My service progress:

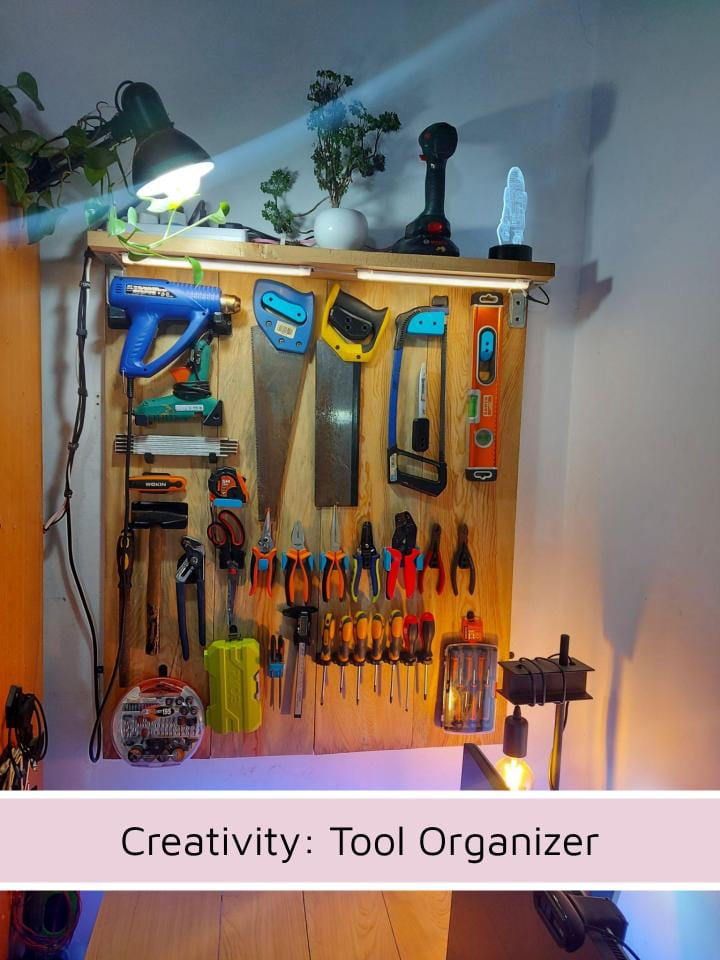

- Since the start of the service semester, the service, recycling and sustainability, has achieved a lot.

- We have restarted our collection of paper and cardboard from each room within the OSC campus, to be sent for recycling.

- We cleaned and reorganized the recycling room, to allow us to store recyclables more efficiently.

- We also did an audit of the rooms, to figure out which rooms required new recycling boxes. And we also began reviving the biogas plant. The biogas plant produces gas when water and food waste is placed into it. Bacteria break down the food, creating gas which we can burn to cook food. However, because of covid restrictions, all the bacteria died off, and it has to be revived. This is done by putting cow manure into the opening, re-introducing the bacteria.

Main Learning outcomes:

#3, Demonstrate how to initiate and plan a CAS experience. We planned out how to revive the biogas plant, how to efficiently collect recyclables , and how to organize the recycling room. These were all service based actions, and they all were planned out.

#4 Show commitment of an percenerace in CAS experiences. For 4 weeks, our service group has been putting cow manure into the biogas plant, to revive it. We also have consistently collected recyclables from every room, every week.